Flasher Hub-12

High-volume gang programming at maximum speed

- 1.Overview

- 2.Key features

- 3.How Flasher Hub-12 works

- 4.Built-in web server

- 4.1.Remote monitoring

- 4.2.Configuration

- 4.3.File management

- 5.Built-in FTP server

- 5.1.Remote file update

- 5.2.Log file

- 6.Flasher Compact — The space-efficient programmer

- 7.Flasher SDK

- 8.Programming FPGAs and CPLDs

- 9.Software

- 10.Supported devices

- 11.Customer support

- 12.Technical specifications

- 13.Product images

- 14.FAQ

Overview

As the big brother of the Flasher Hub-4, the Flasher Hub-12 controls up to 24 Flasher Compact units serving as individual channels for parallel, high-speed gang programming. Each channel can be configured to program a different device or a different firmware image.

The combination of the Flasher Hub-12 and Flasher Compact system is set up once per channel using SEGGER's Flasher software, which is tailored to the type of flash chip being programmed.

The Flasher Hub-12 operates independently via TELNET, with no need for a desktop PC. This combination of a single Flasher Hub-12 and up to 24 Flasher Compacts provides an ideal solution for high-volume, multi-panel, and multi-target mass production.

Key features

Stand-alone operation

The Flasher Hub-12/Flasher Compact system is set up once per channel using SEGGER's Flasher software, tailored to the flash chip type. The Flasher Hub-12 can operate independently via TELNET, without the need for a desktop PC.

High scalability

Flasher Hub-12 allows parallel programming of up to 24 programming units, each serving as an individual channel. It can be connected to up to 24 Flasher Compacts using SEGGER’s USB Hub-7. Each Flasher Compact can be configured individually to program different targets with different firmware.

Complete system configurability

Flasher Hub-12 can be controlled and configured via its built-in web server. Thanks to the intuitive user interface, all necessary information about the entire programming system is available to the user at a glance.

How Flasher Hub-12 works

Flasher Hub-12 facilitates efficient, parallel programming of multiple devices through its integration with Flasher Compact units. Designed for high-speed gang programming, the Flasher Hub-12 offers two distinct operating modes: Direct Mode and Flex Mode.

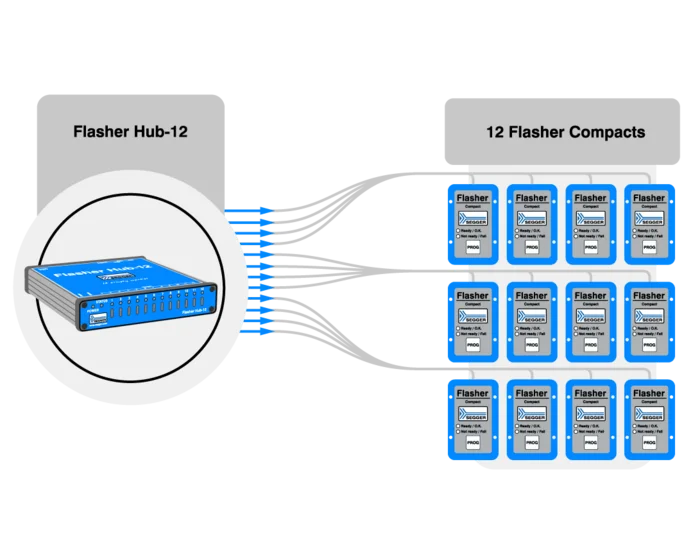

Direct Mode

In Direct Mode, the Flasher Hub-12 manages up to twelve Flasher Compact modules independently. Each module operates as a separate programming channel, directly connected to the Flasher Hub-12 via USB. This mode is ideal for setups requiring straightforward, individual control of up to four devices simultaneously without the need for additional USB hubs.

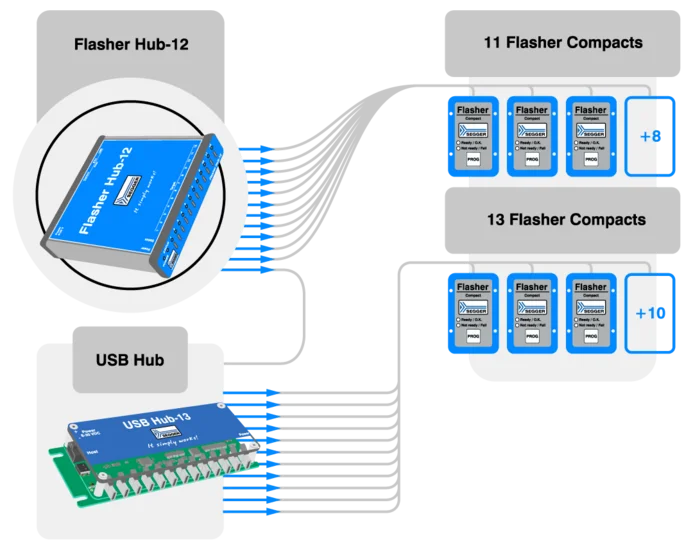

Flex Mode

Flex Mode expands the capabilities of the Flasher Hub-12 by enabling the connection of up to 24 Flasher Compact modules using USB hubs. This configuration provides scalable programming solutions for high-volume production environments where flexibility and efficiency are paramount. In Flex Mode, each Flasher Compact module can be dynamically assigned to any available programming channel, maximizing throughput and adaptability.

Please note: For optimal operation, we recommend using the SEGGER USB Hub-7. SEGGER only provides technical support for setups with SEGGER USB Hubs.

The Flasher Hub-12 is simple to set up and can be operated via TELNET or RS232, utilizing the built-in ASCII command interface, which is optimized for automation. It also includes a user-friendly web interface that allows for easy manual operation, providing intuitive control and monitoring of all connected devices.

Additionally, the Flasher Hub-12 supports programming of unique data that differs between otherwise identical units. This includes serial numbers, Ethernet hardware addresses (MAC), digital signatures, and license keys that enable or disable product features. These unique data pieces can be applied to the firmware during programming, ensuring that each device is customized according to its specific requirements.

Built-in web server

The built-in web server of the Flasher Hub-12 (using emWeb) simplifies configuration and setup of the programming system. In addition, it offers options to check status information remotely and to manage firmware images.

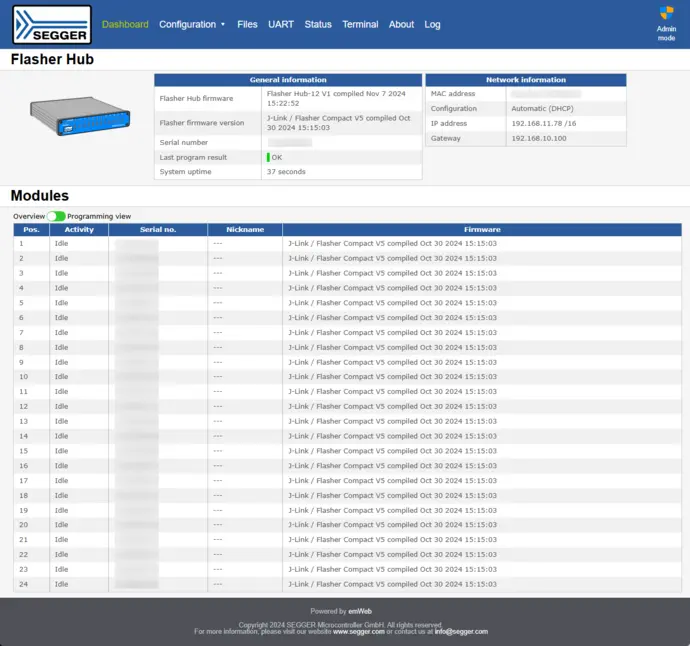

Remote monitoring

The built-in web server is designed to present important device and current operation data for a quick overview and, additionally, to check the status of the programmer, providing information about:

- Installed firmware version

- Hardware version

- Power consumption

- IP configuration

- Network load

- Current operation and status

- Programming interface in use

This may be important for fast troubleshooting through code verification, for instance, as it is when executing a cyclic redundancy check (CRC) that helps to detect errors during data transmission or storage.

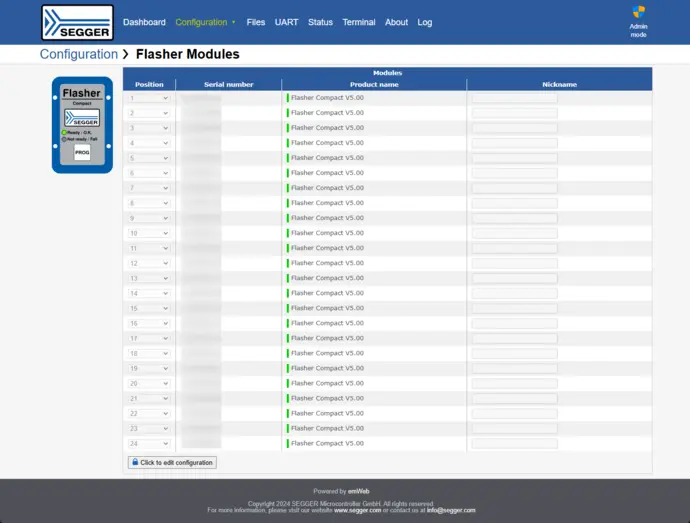

Configuration

If needed, the built-in web server programmer settings can be checked and adjusted. These could, for example, be parameters like:

- Subnet mask

- Gateway

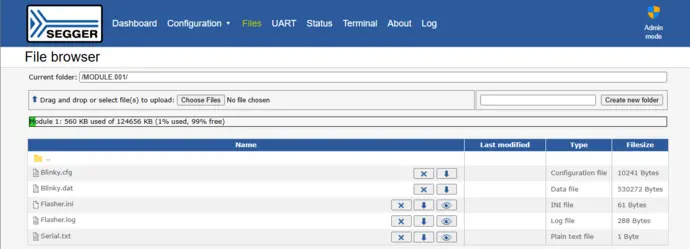

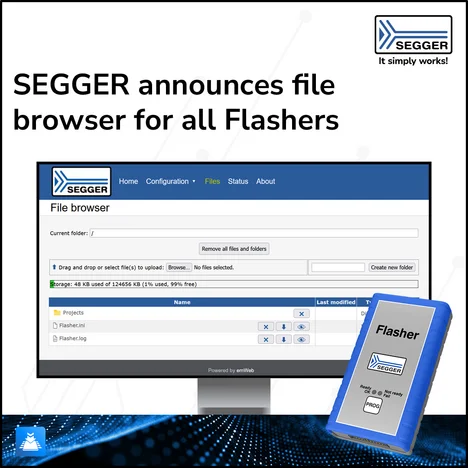

File management

The built-in web server enables file management for all connected modules. This includes

- Firmware images

- Setup files

Built-in FTP server

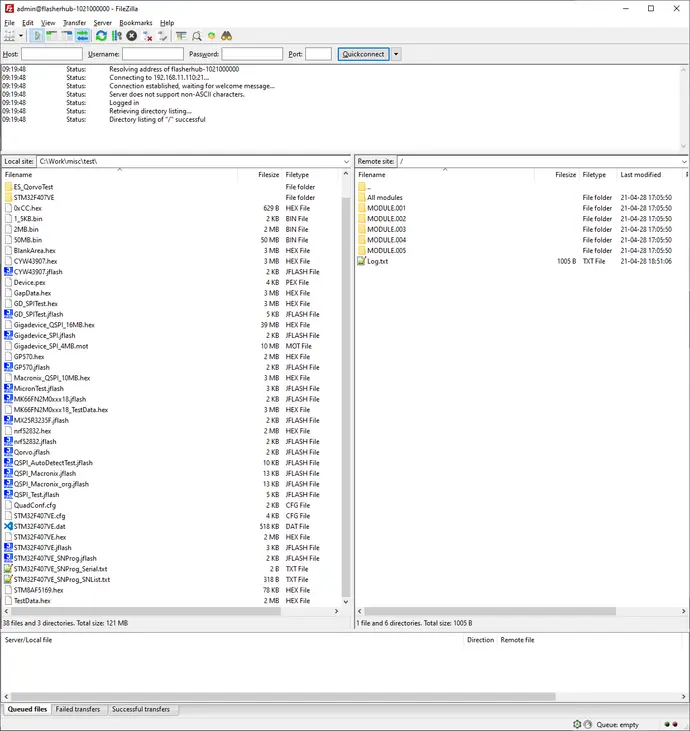

The Flasher Hub-12 also includes a built-in FTP server to upload firmware and configuration or download log files.

Remote file update

Using the emFTP server enables easy upload of configuration files and firmware images. By connecting to the emFTP server using an FTP client of choice, files can be transferred between client and Flasher.

Having access to the Flasher configuration via FTP enables configuration of multiple Flashers from a central production control server. This interface also can be used to make the production line part of a CI/CD system to push stable releases into the current production.

Log file

Analyzing the reliability of the production line is an important task, when it comes to increasing the production speed and volume. This purpose is supported by the built-in FTP server, which lets users check the history of past programming cycles via log file download. Each entry provides the following information:

- Result (success/failure)

- Duration

- Serial number (if programmed)

For failed programming cycles, the log file provides additional information for quick troubleshooting (e.g. failed to open Flasher config file).

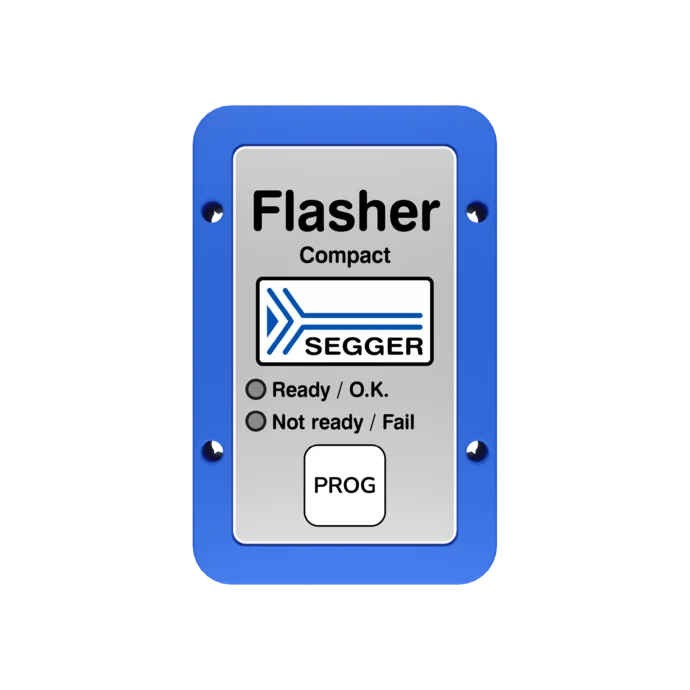

Flasher Compact — The space-efficient programmer

The Flasher Compact is SEGGER’s high-speed, stand-alone in-system programmer. When connected to a Flasher Hub-12, each unit acts as an individual channel for parallel, high-volume programming. It supports a wide range of devices and allows unique data, such as serial numbers or license keys, to be programmed for each target.

Flasher SDK

If a new device is not yet supported by a Flasher, users can add support themselves using the Flasher Software Development Kit. Available in the Web Shop, it includes all documentation, examples, and tools needed to implement programming for custom targets. This makes the Flasher SDK ideal for integrating proprietary hardware or new components into production workflows.

Programming FPGAs and CPLDs

Production departments faced with the task of programming FPGAs or CPLDs do not require the Flasher SDK, as Flasher programmers can program FPGAs and CPLDs using the Flasher BitStreamer.

Software

A multi-platform solution, Flasher Hub-12 comes with SEGGER's Flasher Software and Documentation Package for Windows, Linux, and macOS. It provides the tools and resources necessary for configuring, managing, and using Flasher Hub-12 effectively. It also includes flash loaders for all supported devices, including a wide range of target microcontrollers. The list of supported manufacturers, families and devices, and SoCs provides a detailed overview.

The software package can be downloaded free of charge, and it includes future software and firmware updates as well as all new flash loaders for target devices added in the future.

Supported devices

The list of supported manufacturers, families, devices, and SoCs includes tens of thousands of devices in hundreds of device families.

Device not listed? Please don’t hesitate to contact us.

Customer support

Flasher Hub-12 comes with one year (12 months) of Basic Support. Beyond that, SEGGER's Extended Coverage gives users the option to extend the hardware warranty and Basic Support for one additional year (12 months) or two additional years (24 months). These options are only available at the time of purchase, either through the Web Shop or upon request; adding coverage at a later date is not possible.

Technical specifications

| Specifications | |

|---|---|

| Power supply | 8-30 VDC, reverse polarity protected, max. 60 W[1] |

| Power comsumption | Max. 15 W |

| USB Flasher interface | USB-C 2.0 |

| Host interfaces | USB Type-B (Upstream), USB Type-A (Downstream), Ethernet, RS232 9-pin |

| Operating temperature | + 5 °C ... + 60 °C |

| Storage temperature | - 20 °C ... + 65 °C |

| Relative humidity (non-condensing) | < 90 % rH |

| Size (without cables) | 170 mm x 172 mm x 35 mm |

| Weight (without cables) | 660 g |

[1] Depends on current consumption of connected downstream devices. For maximum load the input supply must provide 12 VDC or more.

FAQ

What is the maximum number of Flasher Compact units supported?

Flasher Hub-4 supports up to four directly connected Flasher Compact units. When used in Flex Mode with supported USB hubs, up to 24 Flasher Compact units can be connected

Can each channel program a different firmware image?

Yes. Each channel operates independently and can be configured with its own programming image and settings. This enables simultaneous programming of different firmware variants within the same production setup.

How can I monitor the programming status?

The programming status can be monitored via the LED indicators on the connected Flashers, through the Flasher Hub ASCII terminal interface, or via the integrated web interface. The web interface provides real-time status information for all connected channels. In addition, programming logs can be retrieved for production tracking and quality assurance.

Latest news

Get in touch with us

Have questions or need assistance? Our Embedded Experts are here to help!

Reach out to us for:

- Licensing quotes

- Technical inquiries

- Project support